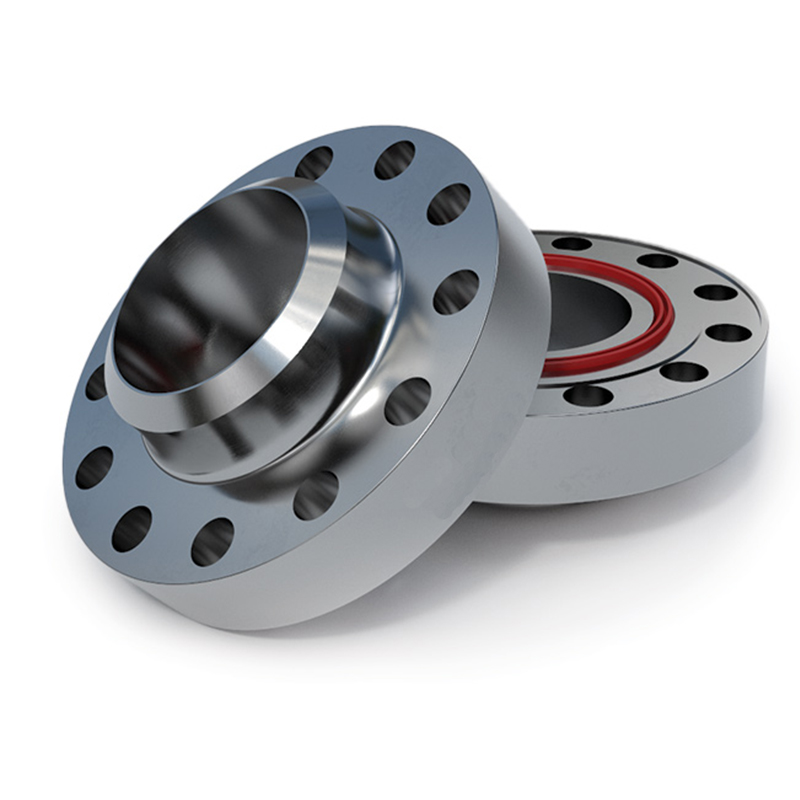

Unveiling the Pitting Corrosion Resistance of ASTM A182 F53 Flanges: In-Depth Analysis through G48 A Method Testing

Abstract: This article focuses on the issue of pitting corrosion of ASTM A182 F53 flanges in specific environments and employs the G48 A method for pitting corrosion testing. The results are analyzed to provide references for material selection, design, and usage of flanges. Introduction: ASTM A182 F53 flanges are widely used in industries such […]